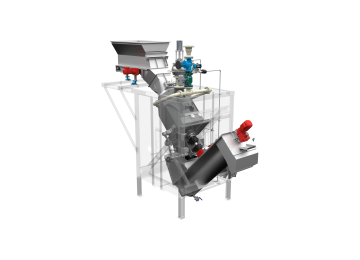

Carborundum Peeler 820

The Carborundum Peeler 820 is designed for contin- uous mechanical peeling of a variety of products in- cluding potatoes, carrots, onions, celeriac, cassava and partially frozen fruits such as oranges and pine- apples. This versatile machine handles tubers, root vegetables and fruit with ease and offers a capacity of 2,500 to 5,000 kg per hour, depending on the prod- uct and degree of contamination.

-

Processes up to 5,000 kg/hour, consistent and reliable peeling.

-

Adjustable roller speeds and grains for different products.

-

Quick-change rollers for minimal downtime.

Thorough peeling

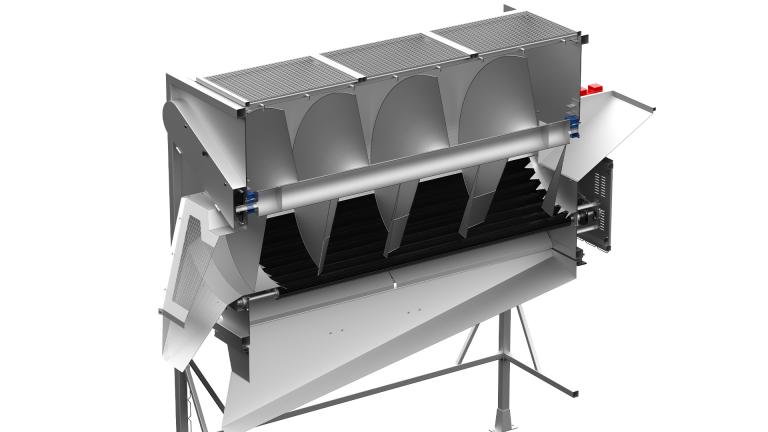

16 peeling rollers, each 3,500 mm long and 105 mm in diameter, ensure thorough and efficient peeling. The rollers are fitted with adjustable carborundum grains to achieve the desired peeling intensity. The quick-change system for the peeling rollers and the adjustable speeds for both the rollers and the screw conveyor optimise the peeling results and reduce downtime.

Adjustable to suit your needs

Manufactured entirely from stainless steel, the Carborundum Peeler 820 is durable, hygienic and designed for efficient operation. It features variable speed gears, a frequency controlled control panel and adjustable water jets to clean peeling waste as required.

Technical data |

|

| Total length | 4520 mm |

| Total width | 2260 mm |

| Total height | 3725 mm |

| Input / Discharge height | 2910 mm / 2000 mm |

| Capacity | 2.500 - 5.000 kg (Depending on product and dirt) |

| Number of peeling rollers | 16 |

| Diameter of peeling rollers | ± 105 mm |

| Diameter worm conveyor | ± 1500 mm |